Factory

Factory

To keep passing the spirit and looks of shitsurai on to the future, SHIKADA SANGYO has been unyieldingly adhering to the techniques we continue to preserve, as well as to which materials and designs we select.

While we value tradition we also take in trends to create new styles, bringing the unparalleled SHIKADA SHITSURAI quality.

While we value tradition we also take in trends to create new styles, bringing the unparalleled SHIKADA SHITSURAI quality.

How we make SHIKADA WOVEN

Making bamboo strips

We choose and cut down good bamboo trees out of grown trees that are three to five years old.

The bamboo is put against a cutter and split evenly to make the base material.

The surface and inner part of the bamboo is split separately.

The split bamboo surface is shaven thinly.

It is then put through a cutter to shred to a few millimeters wide.

The bamboo strings to make SHIKADA WOVEN are completed by splitting the bamboo thinly.

Weaving the bamboo strings (traditional handicraft style Manyo)

The strings are grouped by the color and space between their nodes.

The strings are inserted one by one into the weaver, weaving SHIKADA WOVEN.

Grouped together by whether they are the surface or the inner part of bamboo, the strings are then woven, creating patterns with their nodes.

The curvy part is cut off when creating patterns with the nodes.

Cloth is sewn on to four corners to define the edge.

Bracket and tassels are attached.

Weaving the bamboo strings (standard style SHIKISAI)

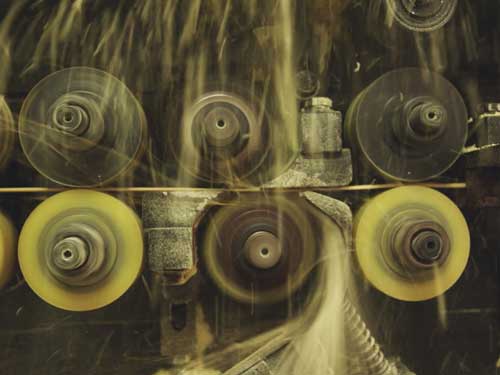

Bamboo strings are inserted one by one into a large weaver, weaving 2.4 m-wide SHIKADA WOVEN.

SHIKADA WOVEN undergoes fire-proof processing.

A mechanism to roll up and down the screen is attached to SHIKADA WOVEN.